Non-Destructive Evaluation & Magnetic Materials

CSIR-NML has both the art of facilities and expertise in the areas of non-destructive evaluation (NDE). Developed through a partial funding from Department of Science & Technology (DST), Govt. of India in 2003, it is now a NDE centre for excellence in India. Some of the key industrial partners of this centre are ISRO, NTPC, Tata Steel, Boeing, IOCL, Bharat Forge, BARC, Aditya Birla.

Damage evaluation using NDE:

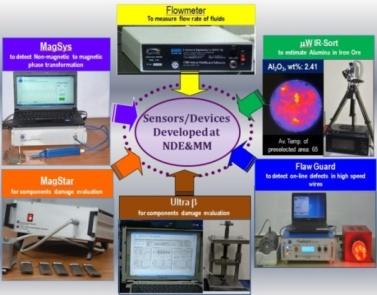

Over the years this group has developed different NDE based methodologies for characterisation of microstructure and assessment of different kinds of damage (residual stress, creep, fatigue, corrosion etc) in various grades of industrial materials. Substantial research activities have been carried out at CSIR-NML for last two decades on NDE and magnetic materials and as a result couple of portable, site-worthy devices have been developed for damage assessment of industrial components. This group is having more than 70 publications, 10 patents, transferred four and commercialised two technologies.

Sensors and Devices for Industrial applications:

Development of Rapidly Quenched Alloys:

The elemental composition design, rapid quenching of alloy melt and post processing of Rapidly Quenched Alloys are one of the important research activities in this group. Rapid quenching technique has an advantage of being a single step process to produce materials with enhanced functional and structural properties, using different direct melt-quenching techniques like planar flow casting (melt spinning), suction casting and in-water quenching. The potential functional materials including metallic glass/ amorphous alloy, bulk metallic glass (BMG) are processed in the form of ribbons (foil), wires, rods and plates for the purpose of various applications, such as, transformer core, giant magnetic impedance (GMI) sensor, metal joining, magnetic shape memory, magneto-caloric, Jewellery items, protective coating for tribology and hydrogen inhibition, EMI shielding etc. Accordingly, CSIR-NML is involved in development of following alloys under different research projects.

- Soft magnetic alloys

- GMI alloys

- Brazing alloys

- Magnetic shape memory & Magnetocaloric alloys