Agglomeration

Agglomeration is a size enlargement process used in the mineral/metallurgical/chemical industries to impart better functionality to products and thus avoiding common processing problems. The Agglomeration Group is engaged in R&D activities related to Briquetting, Pelletization and Sintering of different ores/minerals/industrial waste. The Group is equipped with the facility to carry out sintering, brequtting anmd pelletization studies and evaluation of agglomerated products. These include determination of Cold Crushing Strength, Shatter and Tumbler indices, Blaine number, Reduction index, Reduction degradation index, Thermal degradation index. Presently the Group is involved in pelletization of fine grained iron ore and chromite concentrates and briquetting of wastes from iron and steel making. Agglomeration methods can be broadly divided in three different categories:

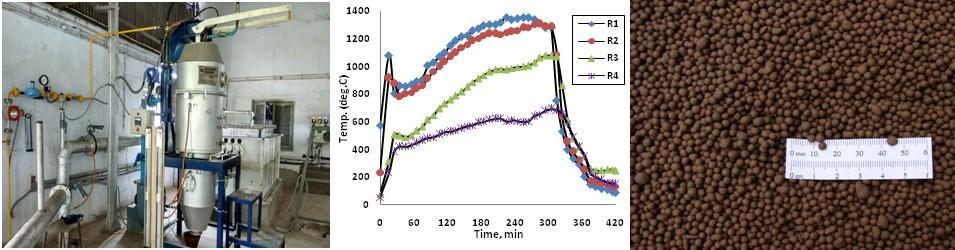

Pelletization : This primarily consists of two distinct operations, namely, forming the green balls called pellets at atmospheric temperature and then firing them at a temperature below the softening temperature. Iron ore fines and concentrates are ground to suitable fineness and mixed with some quantity of moisture and a suitable binder e.g.,

bentonite, lime etc and the mixture rolled in either a horizontal drum or an inclined disc. At this stage, the spheres known as green balls or pellets have adequate strength to withstand handling to the firing stage. This is followed by pellet firing, called induration. During induration, besides change in crystal structure the other bonds appear by reactions between slag forming constituents – both between each other and with iron oxides. In ‘Cold bonded pelletisation’, binders like calcium hydroxide or cement is added during green ball formation. They are indurated by using steam under high pressure in an autoclave or keeping the green pellets under moist condition over a long period of time.

Briquetting : This is a simple process involving agglomeration of fine grained materials by pressing into briquettes

with the addition of moisture and/or another binder under high mechanical pressure. The briquettes may be subjected to further treatment or thermal processing before their use.

Sintering : In sintering fine mineral particles are agglomerated into a porous mass by incipient fusion caused by the heat produced by combustion within the mass itself. In this case the iron ore fines and other iron bearing recycling materials are mixed with fluxing material, moisture and solid fuel normally coke breeze and fed to the permeable grate of sintering machine. The upper surface is ignited and the air is drawn through the bed with combustion front passes downwards accompanied by a series of physical and chemical changes which produce the sinter.